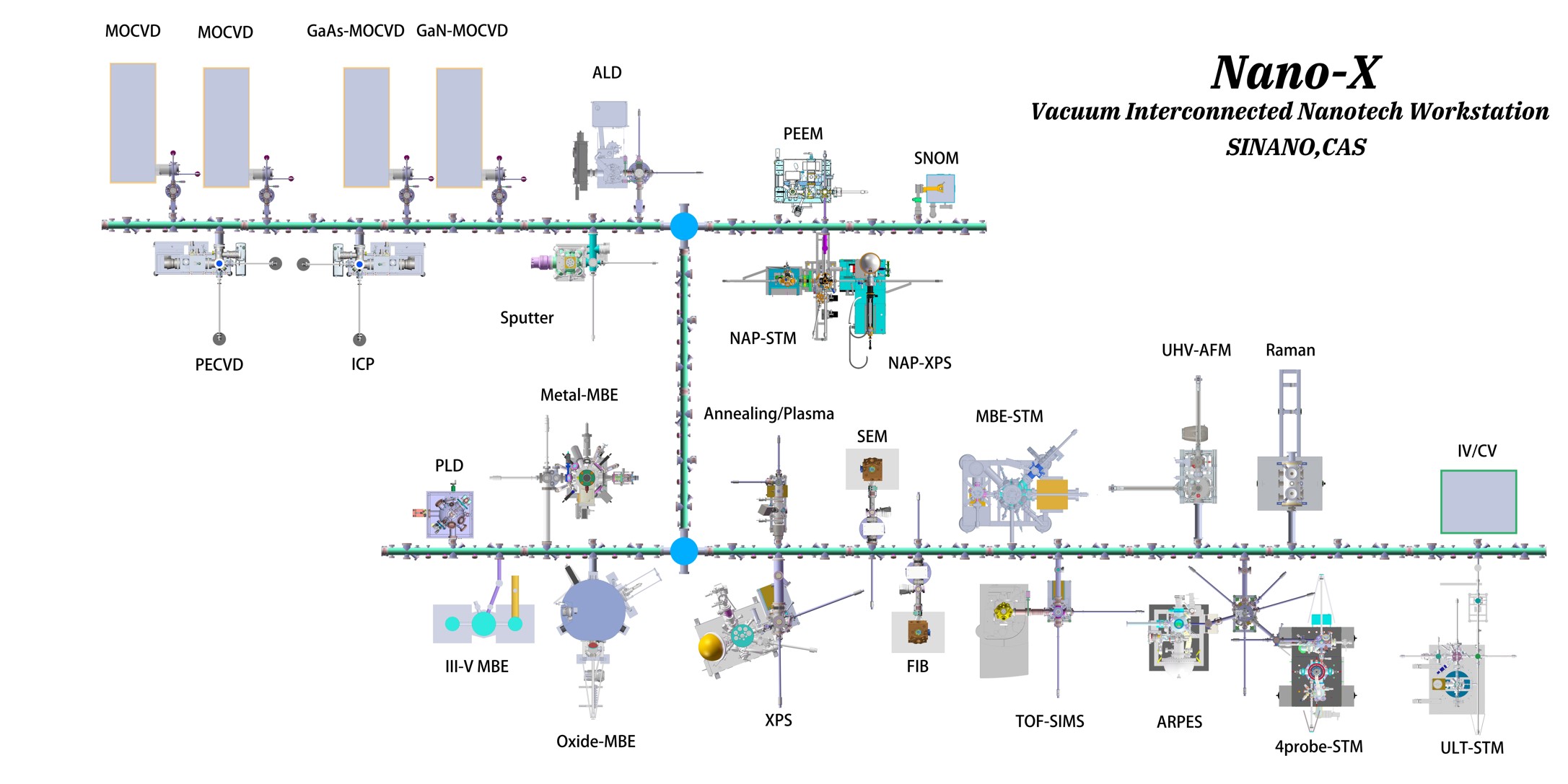

Vacuum Interconnected Nanotech Workstation

| Vacuum Interconnected Nano-X Research Facility (NANO-X), integrating all processes of material growth, characterization, and device fabrication in one ultra-high vacuum environment, is capable to explore the intrinsic properties of the materials and devices, develop novel technologies for device fabrication. Therefore, to simplify and shorten the development process from fundamental researches to industrial applications. Also, NANO-X is going to essentially change the traditional research methods in classical physics, solve the critical technical problems in the emerging industries, and therefore to promote the new industrial chain and upgrade the technology infrastructure in Jiangsu Province, also to build the "Suzhou upland" in nano-tech industry. Based on this revolutionary technology of vacuum interconnection, followed the national strategy of "Made in China 2025", NANO-X is going to improve the capability of system design and integration, breakthrough the technologic limitations in industrialization, enhance the abilities of innovation and competition, attract the talents in nanotechnology around the world. Layout Nano-X is designed as a whole system with about one hundred pieces of equipment, for materials growth, device fabrication and test, interconnected by hundreds meters of ultrahigh vacuum pipelines (base vacuum better than 5X10-8 Pa). All wafers/samples can be transferred accurately, quickly and smoothly among all tools in ultra-high vacuum environment. Nano-X is able to maximally prevent surface contaminations from the ambient. Therefore, to keep the material intrinsic properties unchange and to realize atomic manipulation and control in quantum devices.

|